Unlocking the Potential of Bendable Metal Arms: Innovations, Applications, and Future Trends

In the rapidly evolving landscape of manufacturing, robotics, automation, and creative engineering, bendable metal arms have emerged as a pivotal component driving flexibility, precision, and efficiency. Companies such as flexible-arm.com lead the industry by offering cutting-edge solutions that redefine what is possible with adaptable metal structures. This comprehensive guide delves into the core aspects of bendable metal arms, exploring their design principles, manufacturing techniques, diverse applications, and future trajectory in advancing industrial and commercial sectors.

Understanding Bendable Metal Arms: What Are They?

Bendable metal arms are highly adaptable, flexible structures composed primarily of metals engineered to be both robust and malleable under specific conditions. Unlike traditional rigid arms used in machinery and robotics, these innovative components can be shaped, re-shaped, or adjusted dynamically, providing unparalleled versatility for various applications. They are typically manufactured using advanced alloys that balance strength, flexibility, and durability.

The fundamental characteristic of bendable metal arms lies in their ability to sustain multiple bending operations without fatigue or loss of structural integrity. This ability makes them invaluable in fields where agility, precise positioning, and multi-directional movement are essential.

Design Principles of Bendable Metal Arms

The functionality and performance of bendable metal arms are rooted in their sophisticated design principles, which focus on optimizing flexibility, strength, and lifespan. Key factors include:

- Selecting the right materials: The backbone of bendable arms typically comprises high-performance alloys such as memory metals (e.g., Nitinol), stainless steel, or specialized composites that exhibit superior elasticity and fatigue resistance.

- Engineering the cross-section: The cross-sectional geometry influences the bending radius, load-bearing capacity, and flexibility. Engineers often employ I-beam, circular, or custom profiles tailored to specific needs.

- Incorporating precise bending points: Strategic placement of bend points ensures smooth articulation, often facilitated through bends, joints, or flexures integrated into the metal structure.

- Ensuring fatigue resistance: The metallic structure must endure repeated bending cycles, demanding meticulous material selection and design to prevent cracks or failures over prolonged use.

Manufacturing Techniques for Bendable Metal Arms

Creating high-quality bendable metal arms involves advanced manufacturing processes that ensure consistency, precision, and longevity. Notable methods include:

1. Precision Metal Forming

This technique encompasses stamping, deep drawing, and curling to shape metals with extreme accuracy. Computer Numerical Control (CNC) machines are often utilized to produce complex geometries with minimal tolerance deviations.

2. Heat Treatments and Shape Memory Alloys

For alloys like Nitinol, heat treatment processes such as annealing are critical to achieve the desired superelastic properties, allowing the arms to bend extensively and revert to their original shape.

3. Bending and Flexure Integration

Advanced bending techniques, often guided by robotic arms themselves, ensure precise curvature and flexibility. Flexures—thin compliant elements—are integrated to allow smooth, continuous motion without traditional joints.

4. Additive Manufacturing

With the advancement of 3D printing technologies using metal powders, complex bendable metal arms can be produced with integrated features, optimized weight, and tailored mechanical properties.

Key Applications of Bendable Metal Arms

The versatility of bendable metal arms opens up a multitude of applications across various industries, transforming traditional workflows and introducing new capabilities.

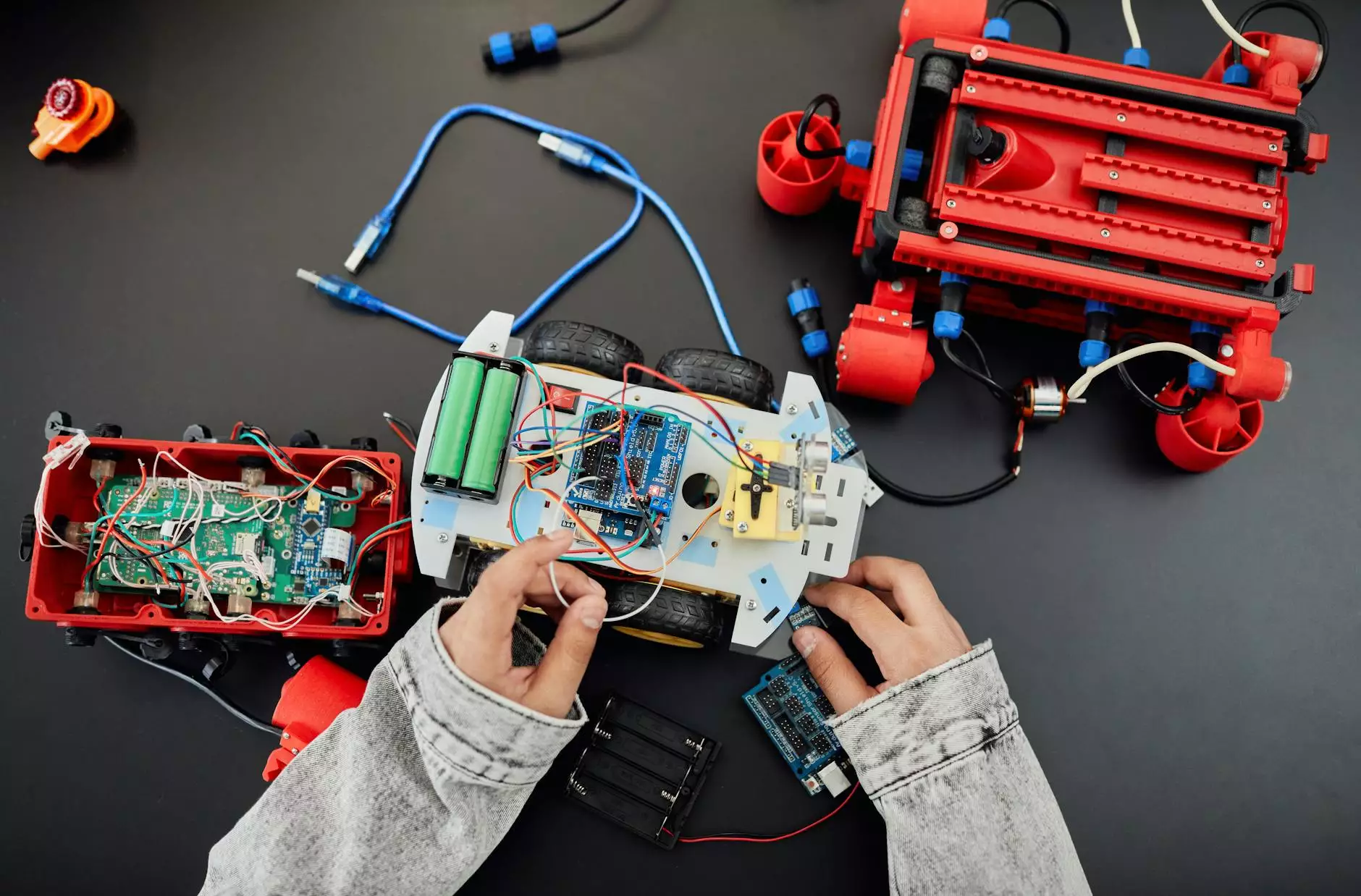

1. Robotics and Automation

In modern robotics, bendable metal arms are employed to create flexible robotic appendages capable of intricate movements, especially in environments requiring gentle handling or complex manipulation. This flexibility enhances robots used in manufacturing lines, medical instruments, and delicate assembly operations.

2. Medical Devices and Surgical Instruments

Precise, flexible, and sterilizable, bendable metal arms serve as critical components in minimally invasive surgical tools, endoscopes, and robotic surgery systems where patient safety and instrument maneuverability are paramount.

3. Aerospace and Defense

Lightweight, high-strength bendable metal arms contribute to adaptable antennae, sensor mounts, and robotic assembly units in aerospace applications, where precision and reliability are critical under extreme conditions.

4. Consumer Electronics & Artistic Installations

Innovators leverage bendable metal arms to design adjustable lighting rigs, dynamic sculpture supports, and flexible mounts, enabling creative expression and user-friendly interfaces.

5. Automotive Engineering

In the automotive industry, flexible metallic components assist in developing complex sensor systems, adjustable mirrors, and innovative control systems that adapt seamlessly to different driving conditions.

Advantages of Using Bendable Metal Arms in Business

Incorporating bendable metal arms into your engineering and business solutions offers numerous benefits:

- Enhanced Flexibility: Allows devices and systems to adapt dynamically to environmental challenges or operational demands.

- Reduced Maintenance Costs: Fewer moving parts and joints decrease wear and tear, prolonging service life.

- Greater Precision: Enables intricate movements that are critical in delicate tasks such as medical procedures or precision manufacturing.

- Lightweight Design: Advanced alloys ensure low weight without compromising strength, thereby improving energy efficiency.

- Customization and Scalability: Easily tailored to specific needs, whether small-scale prototypes or large industrial systems.

Choosing the Right Bendable Metal Arm Supplier

Partnering with a reputable manufacturer such as flexible-arm.com guarantees the quality, durability, and innovation needed to stay competitive. When selecting a supplier, consider the following:

- Material Expertise: Do they utilize cutting-edge alloys like Nitinol or advanced composites?

- Customization Capabilities: Can they tailor designs to your exact specifications?

- Industry Experience: A track record in your specific application sector boosts reliability.

- Quality Assurance: Certifications, testing procedures, and quality control protocols are critical indicators.

- Research & Development: Companies investing in innovation stay ahead of technological trends.

Future Trends in Bendable Metal Arms

The evolution of bendable metal arms is directly correlated with advances in materials science, robotics, and intelligent systems. Emerging trends include:

- Integration with IoT: Embedding sensors within bendable arms for real-time data collection and autonomous operation.

- Enhanced Smart Materials: Development of new alloys that offer shape memory, self-healing, or adaptive properties.

- Miniaturization: Making micro-scale bendable arms for use in nanotechnologies or medical micro-robots.

- Artificial Intelligence Integration: Enabling self-learning and adaptive control for complex tasks without human intervention.

- Sustainable Manufacturing: Focus on eco-friendly materials and processes to reduce environmental impact.

Conclusion: Embracing the Power of Flexibility with Flexbile-arm.com

As industries continue to pursue innovation and operational excellence, bendable metal arms stand out as a transformative technology. They enable engineers and designers to overcome traditional limitations, resulting in smarter, more adaptable, and efficient solutions. Companies like flexible-arm.com are leading the way by providing custom, high-quality bendable metallic components that can be integrated into a variety of applications.

Whether you are developing cutting-edge medical devices, enhancing robotic systems, or creating artistic sculptures, investing in bendable metal arms unlocks new possibilities—and the future of flexible, resilient metallic components is brighter than ever. Explore how this innovative technology can elevate your projects and propel your business forward in an increasingly dynamic world.